🚧 "Zero slump concrete is not a defect, but a requirement in precast and dry-cast applications where high strength and shape retention are critical."🚧

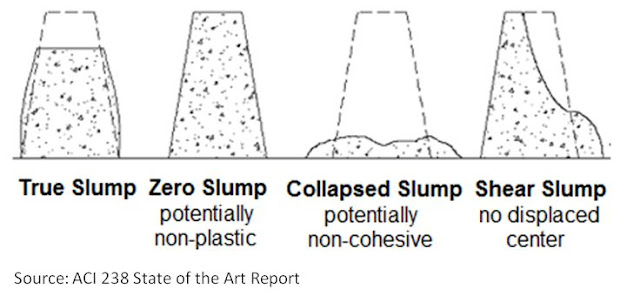

Zero slump concrete is a type of concrete that has very low workability, meaning it does not flow or deform under its own weight when tested using the slump test. In fact, during the test, it retains its original shape completely, indicating a slump of 0 mm, hence the name zero slump.

🔥 Characteristics of Zero Slump Concrete

➡️ Very stiff and dry mix.

➡️High cohesion and internal friction.

➡️Requires mechanical compaction (e.g., vibration or tamping).

➡️Usually has low water-cement ratio.

➡️Not suitable for areas needing flowable or pumpable concrete.

🔥Applications and Uses of Zero Slump Concrete

Zero slump concrete is primarily used in precast and mass concrete applications, where high strength and low permeability are critical, but workability is not.

1. Precast Concrete Products

-Blocks, pipes, and tiles: Many of these are manufactured using zero slump concrete because it's easy to mold under pressure and gives sharp edges and dense, strong units.

-Railway sleepers: Requires durability and strength, often cast with zero slump concrete.

-Paving stones and slabs: These need a stiff mix to maintain shape and surface finish.

2. Road and Pavement Construction

-Roller Compacted Concrete (RCC): Used for heavy-duty pavements, industrial floors, and highways. RCC is a form of zero slump concrete that is compacted using rollers.

3. Mass Concrete Work

-Large dams, retaining walls, and foundations, where flowability is not necessary and strength and volume stability are more important.

4. Concrete Pipes

-Used for sewer systems, culverts, and drainage: the dry mix allows better handling and casting in molds with vibration.

🔥Advantages of Zero Slump Concrete

⛳Higher strength and durability due to low water content.

⛳Reduced shrinkage and cracking.

⛳Excellent dimensional stability.

⛳Better surface finish in precast components.

🔥 Limitations

❌ Difficult to place and compact manually.

❌Not suitable for reinforced concrete in complex shapes or where formwork is intricate.

❌Requires special equipment for mixing, placing, and compaction.

🧱 Practical Note:

In site or lab testing, even a slight disturbance during lifting of the slump cone may cause a 5–10 mm drop. So, some engineers refer to 0–10 mm as the effective zero slump range, but true zero slump is always 0 mm.

0 Comments